Self-lubricating bushings technical features

Find out all about our advice on the processing and technical characteristics of self-lubricating bushings : machining, assembly and sizing of bushings.

Machine, assembly and sizing a

Metafram bushing.

Machining a

bushing.

Sometimes applications or uses do not match the range of self-lubricating rings offered by Metafram. For large series, it may be interesting to contact us to study the possibility of serial tooling. Otherwise, good news, Metafram self-lubricating bearings are machinable.

Assembly a

bushing.

Discover our tips for optimum assembly and use of Metafram self-lubricating bearings.

We can also guide you if you need special assembly.

Sizing a

bushing.

Correct sizing of a sintered self-lubricating bushing increases product life and reduces the risk of failure.

Used under ideal conditions, a Metafram ring can last for tens of years.

Machining a

Metafram bushing.

Why machine a self-lubricating bushing ?

Whether it is BP25 bronze, FP20 iron or SO16, it may sometimes be mandatory to go through a machining phase of the bearings. This machining generally occurs in two major cases :

- creating a part from a blank : In this case, the part is made by machining from start to finish. When the series become more important it can be interesting to go through a tool creation. At Metafram we have a wide range of machining blanks.

- Finishing a part by machining : The powder metallurgy and sintering processes have many advantages, but some forms are not feasible. A stage of reworking is sometimes necessary (reworking chamfers, flanges, etc.).

Guide to machine a

Metafram bushing.

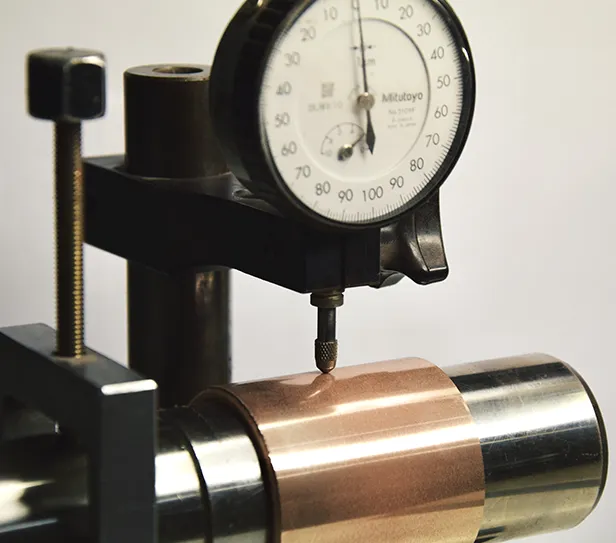

In the machining guide you will find the recommendations that will allow the Metafram bushing to retain all of its characteristics. The goal is to work the bearing while maintaining the porosities on the work areas in order to guarantee the self-lubrication of the material.

Recommendations are made on the different stages of machining a ring such as turning, drilling or tapping. The cutting conditions vary depending on the BP25 bronze, FP20 iron or SO16 material when machining the self-lubricating bushing.

After machining, washing and then re-impregnation is required to give the pad its self-lubricating characteristics.

If these steps are not performed correctly, the life of the bearing may be severely impacted. If in doubt, do not hesitate to contact us.

Assembling a

self-lubricating bushing.

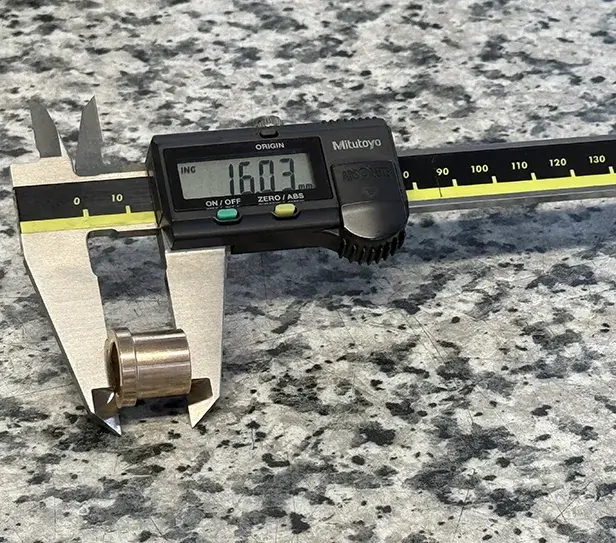

Assembling a Metafram bronze bushing requires some precautions. For optimum use, the bushing must be fitted with a mandrel with M6 tolerances. This bushing must systematically be press-fitted to guarantee its perfect positioning and thus respect the tolerances of the bearing after fitting.

The change in tolerances of the

Metafram bushing.

Tight fitting of a Metafram bushing involves a change in tolerances. Housing tolerances must be in H7. The clamping between bushing and housing and the final bushing bore tolerances were determined for a rigid housing of steel or, in a pinch, cast iron. For any other housing (non-rigid or any other material), the tightening constraints being different, plan practical tests to define the bore tolerances.

The operating clearance of a

Metafram self-lubricating bushing.

It is essential to observe the operating clearance for Metafram bearings. This set allows for optimum operation and lubrication. Failure to follow this recommendation may result in insufficient lubrication and premature bearing wear.

The optimal setup is a running game in H7 / f7 or H8 / f7

Determination of the

shaft speed.

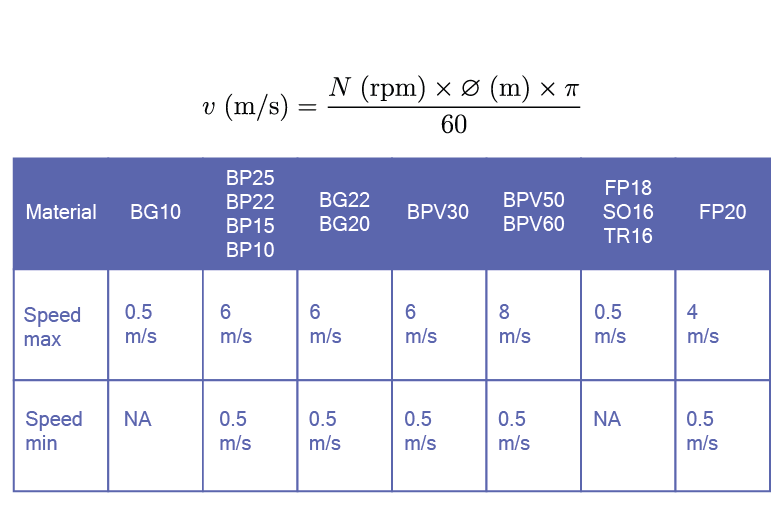

Speed is a determining factor in the sizing of a Metafram bushing. In order to be able to determine this speed at the point of contact between the bearing and the shaft, it is important to have the following information :

- N : The speed of rotation of the shaft in revolutions / minute (rpm)

- Ø : The shaft diameter in meters (m)

Determination of the

Load on the shaft.

The load on the shaft is the second element to be determined for the correct sizing of a Metafram bushing. For this you need to know your application and the force that is applied to the bearing.

On the side of the sinterted bushing, it is important to determine the force exerted on it.

To do this, it is necessary to have the following 3 pieces of information:

- F : The load of the shaft on the bearing (daN)

- Ø int. : the internal diameter of the self-lubricating bushing (cm)

- Long. : the length of the self-lubricating bushing (cm)

Determination of the

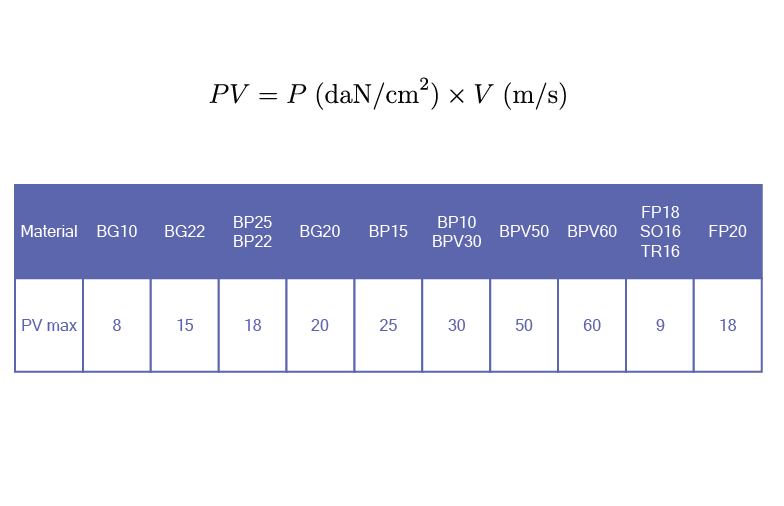

PV.

Speed and load multiplication is essential for a sintered self-lubricating bushing. The higher the load, the lower the speed must be to preserve the Metafram ring and vice versa.

This multiplication is calculated very easily with the product of the speed and the load.

Find the shaft that matches

the sintered bearing.

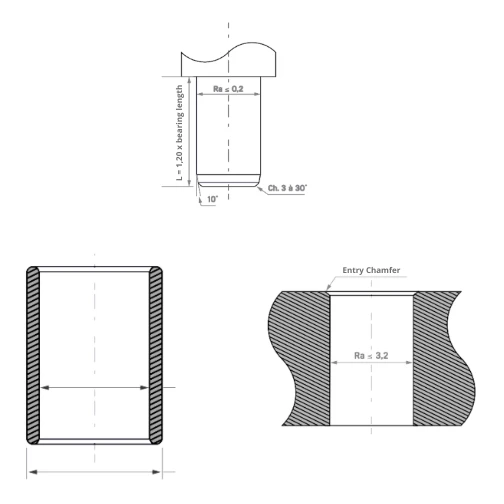

The last parameter to consider when choosing the sintered self-lubricating bushing is the shaft. While respecting the operating clearances stated in the brochure, the shaft must have a defined roughness and hardness depending on the material of the Metafram bearing.

A shaft that is too hard, with a high roughness, will prematurely deteriorate the bearing. Conversely, a shaft that is not hard enough will wear out on contact with the bushing, it is generally better to wear out the bearing rather than the shaft because it is easier to replace.

The characteristics of the recommended shaft are shown below :