Self-Lubricating friction plates

Tailor-made self-lubricating plates for your advanced industrial needs.

Self-Lubricating friction plates

Metagliss

Our specialized brand.

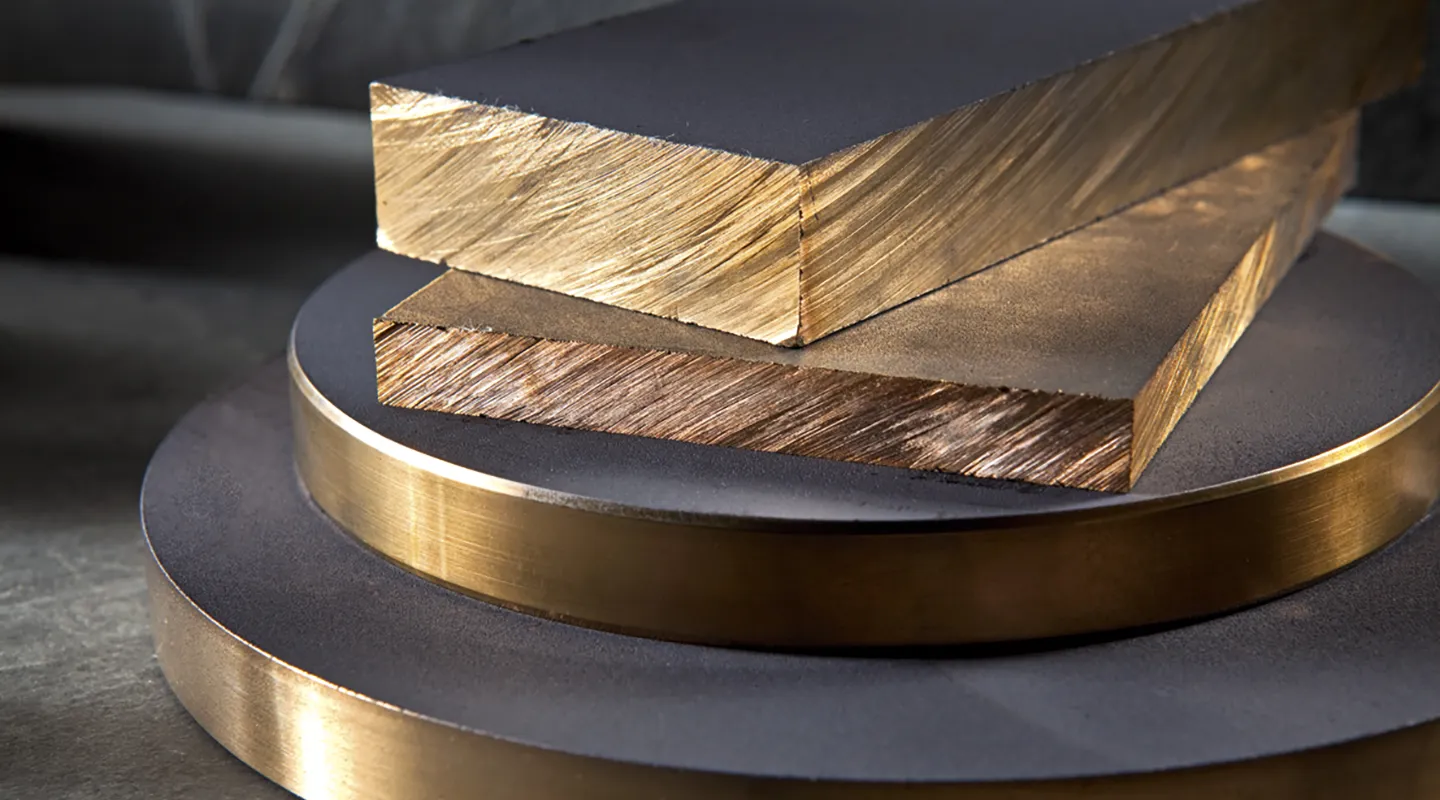

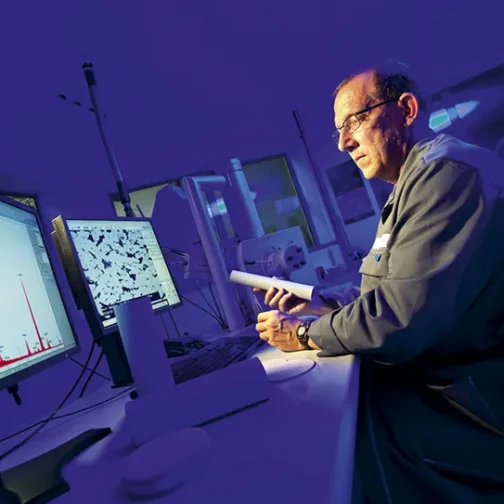

Metagliss specializes in the design and manufacture of self-lubricating friction plates, thanks to its expertise in powder metallurgy. Self-lubricating friction plates are manufactured by sintering metal powders. They are an innovative solution for improving industrial performance.

Self-Lubricating friction plates :

an innovative solution.

An innovative solution that integrates continuous lubrication into the component, thanks to a microporous structure that gradually releases oil. The advantage of these plates is that they do not require the addition of external lubricants, and enable the performance of mechanical systems to be greatly optimized.

The industrial applications are very varied, ranging from general and industrial mechanics to high-tech industries such as aeronautics.

Advantages of

Self-Lubricating friction plates.

- Reduced wear and tear on equipment

- Optimized machine life

- Reduced maintenance costs

With METAGLISS, you benefit from the expertise of a brand that’s been around for over 70 years, and from personalized support tailored to your industrial needs.

Manufacturing process for

Self-Lubricating friction plates.

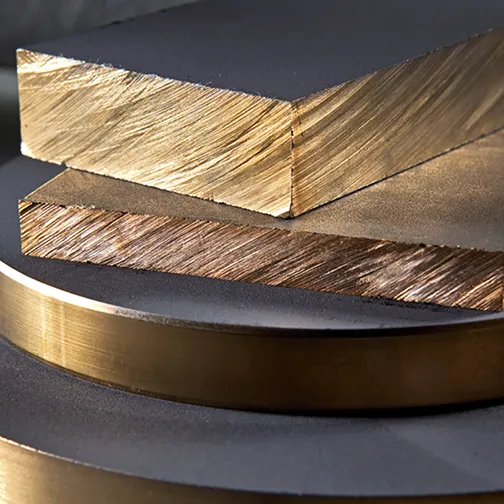

Self-lubricating friction plates are made by sintering metal powders, usually bronze. The resulting structure is a microporous part that can absorb oils.

Powder preparation & forming

The process is based on powder metallurgy, enabling the creation of parts with a high degree of precision and a porous structure. First comes the selection and preparation of metal powders, often bronze. These are mixed with special additives, notably lubricants.

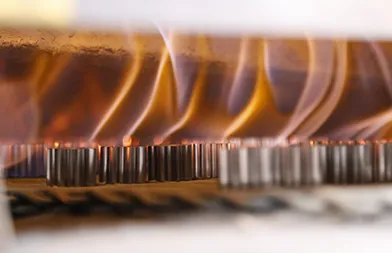

Sintering phase

The metallic powders are compressed to form parts close to their final shape. Once compressed, the parts are heated to a temperature below the melting point. During this phase, diffusion bonds the metal particles together, while maintaining the porosity essential for lubricant storage and release.

Post-treatment & finishing

After sintering, additional treatments are applied to the plates. Plates can be impregnated with specific oils and sometimes coated with a film of molybdenum disulfide (MoS2) for optimum performance in the most demanding industrial environments.

Metafram

Our other brand

Metafram.

Metafram self-lubricating bearings and bushings are designed to deliver reliable performance across a wide range of speeds and loads.

Discover Metafram, for

Self-lubricating bearings.

By integrating lubrication directly into the material, they minimize maintenance needs while extending service life. With specialized alloys such as bronze for high-speed applications and ferrous compositions for extreme loads, Metafram bearings provide durable and efficient solutions for even the most demanding industrial environments.

Do you have a question or a project?

Access our contact form and our teams will get back to you as soon as possible.